Precision Made Simple: Enhance Your Powder Sampling with JETSPRAY®

The sampling process is tedious yet one of the most critical processes to ensure batch consistency and purity of the product.

By Charles Pandian

The sampling process is tedious yet one of the most critical processes to ensure batch consistency and purity of the product. A variety of sampling methods are used in the industry. Each type of sampling process has its benefits and limitations. In this blog, we discuss the significance of powder sampling, the types of sampling techniques and the advantages of employing sampling ports.

Dive in to learn more.

What is Powder Sampling in Pharma?

Powder Sampling is a process in which a small, representative portion of powder or granules is collected from a large batch during manufacturing. This sample acts as a quality checkpoint, ensuring that the entire batch complies with the regulatory standards before proceeding to the next step in production.

Significance of Powder Sampling

Powder sampling is crucial for the following reasons:

- Helps to keep a check on Quality:

By sampling powders, manufacturers can detect any changes in particle size, moisture content, or composition at the early stage, helping ensure product uniformity.

- Assures Regulatory Compliance:

The regulatory authorities strictly check the products produced by the Pharma, Food, and Chemical industries. A consistent sampling of the powders guarantees compliance with the stringent safety and quality standards.

- Optimization of the Process:

The data obtained from the sampling process allows manufacturers to fine-tune the production parameters to improve the process efficiency and reduce waste.

- Batch Verification:

The analysis of powder samples allows manufacturers to confirm the homogeneity of the product and verify that it meets the expected specifications before upscaling the production.

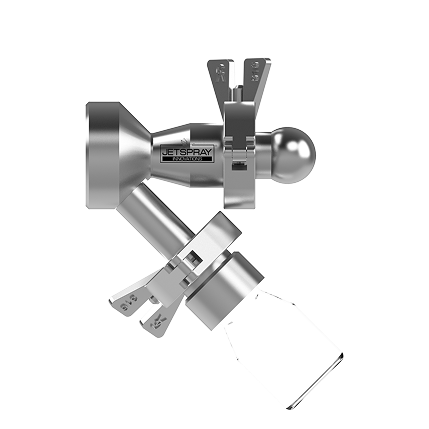

Simplify your Sampling Process with our Sampling Ports

Our Sampling ports offer one of the most reliable devices to ensure representative powder samples. With our intuitive ports, the herculean task is executed effortlessly, and the samples are collected directly from granulation and drying equipment, flowing into a glass bottle attached to the discharge port.

The smart sampling ports not only help streamline the process but also ensure a clean and precise sample each time. These are designed for free-flowing powders and granules, and the sample is collected at atmospheric pressure.

Take a look at the key features:

- Easy Operation:

Our ports have an ergonomic push/pull action that allows for quick and seamless sample collection without requiring any specialized technique or training.

- Versatile Applications:

Jetspray’s Sampling port can smoothly integrate into any process, including fluid bed equipment, spray dryers, and other blending systems. Our ports guarantee consistent results every time.

- Clean and Accurate:

Since the samples are collected in a glass bottle attached to the discharge port of the valve, it reduces any risk of contamination while ensuring precision in sample retrieval.

- Operated at atmospheric Pressures:

Our sampling ports are engineered to be used in atmospheric pressures. They offer dependable performance in diverse manufacturing environments, including granulation and drying processes.

- Improved Efficiency:

Our Sampling ports are designed to streamline your workflow. With these ports, you can reduce sampling time and increase productivity. Its intuitive operation helps minimize interruptions and improves the production line.

Technical Details

Type: Manual or Actuated Piston

Size: Lab Scale & Production Scale Models

Material: Stainless Steel

Pressure: Atm

Temperature: 0°C to +150°C

Int. Surface Finish: 0.8 Ra

Ext. Surface Finish: 3.0 Ra

Sealing Materials: Food-grade Silicone

Sample Unit: Borosilicate Glass Bottle

For more information about sampling ports, visit JETSPRAY now.

Share on

Tags: Product Sampling

(1).png)